Our products have been part of people’s meals at home for generations, offering nutrition through our shelf-stable, plant-based, culinary food behind brands that people trust

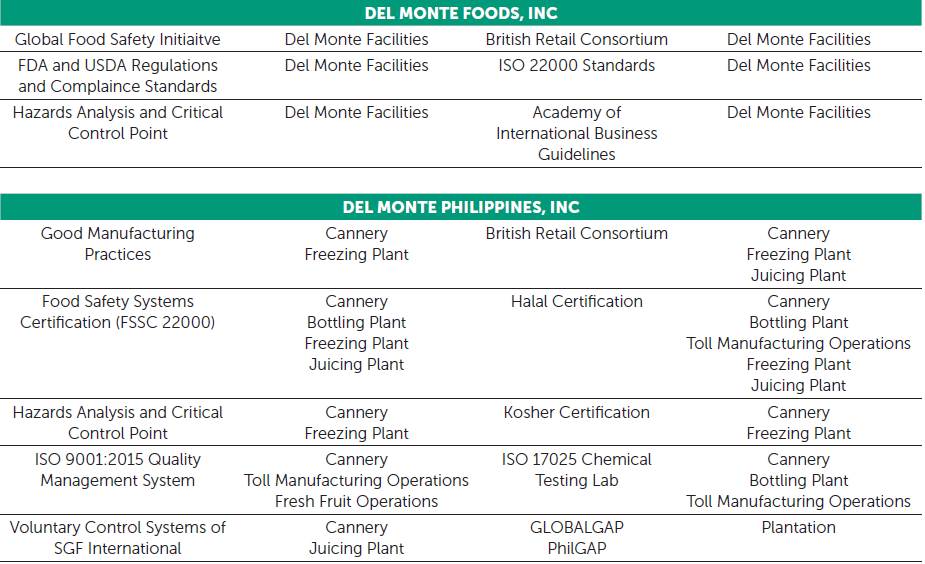

The Group ensures that consumers understand our commitment to providing food products that conform to food safety standards and regulatory requirements through a food safety management system. We require our toll manufacturers to adhere to the same commitment in delivering our products to market.

The requirements for our products worldwide, Global Food Safety Initiative (GFSI) and Food Safety Systems Certification (FSSC), incorporate key systems – International Standards Organisation (ISO), Hazard Analysis and Critical Control Points (HACCP) and Good Manufacturing Practice (GMP) standards into a single system.

1. Del Monte Foods, Inc (DMFI) built a multi-layered quality system protocol that starts with our executive leadership establishing the Company’s quality protocol. This is deployed to each of our facilities to provide guidance and direction and is further supported by our manufacturing site procedures.

2. Preventive Controls Qualified Individual (PCQI) certificates are given to all facility managers in the United States as part of the Food Safety Modernisation Act.

3. Our agro-industrial processes are accredited by the world’s leading food certifying bodies, GFSI or British Retail Consortium (BRC), with 26 quality audits across our production facilities and toll manufacturers in the US.

4. The Quality Policy of Del Monte Philippines, Inc (DMPI) is committed to Total Customer Satisfaction in providing food products that meet the highest global standards in quality, food safety, hygiene and service.

5. Facility managers of Toll Manufacturing facilities exporting to the US also have PCQI certificates.

“There are no old roads to new directions.”

The Boston Consulting Group

Innovation is at the heart of being able to nourish families with healthy food. Significant strides have been made in introducing nutritious and environment-friendly products to consumers. It is our hope that by doing so, we are able to enrich lives every day.

Del Monte Foods R&D Team

1. Consumers are increasingly seeking plant-based foods that provide a healthier and more sustainable way to incorporate protein into their diet. Del Monte began to address these consumer needs and trends by bringing added nutrition to the Vegetable category.

2. Del Monte Veggieful Bites provide a serving of vegetables that help consumers meet their daily vegetable serving recommendation.

3. DMFI introduced the shelf-stable meal alternative, Del Monte Veggieful Veggie Bowls. The product features a blend of veggies and whole grains for a wholesome snack or meal. Each bowl includes one full serving of vegetables.

4. Veggieful introduced a new line of vegetarian pocket pies. The pocket pies are a handheld snack with plant-based ingredients and real cheese that are better for consumers and the environment. Each pocket pie has one full serving of vegetables baked in a crust made with cauliflower and wheat flour.

5. Contadina introduced Pizzettas, a bite-sized pizza snack that includes one full serving of vegetables and features a blend of Roma tomato sauce and cheese stuffed in a crust baked with cauliflower.

6. College Inn introduced the Simple Starter, a meal-starter made of stock and herbs for one-pot meals. Simple Starter is made with 100% natural College Inn stock. It creates the foundation for endless recipes where consumers can just add their favourite protein, starch and veggies to create a hearty, home-cooked meal.

7. Del Monte Fruit & Chia is the first in the market to combine a whole serving of fruit with wholesome chia seeds, giving a full cup of flavour, fibre and 800mg of omega-3.

8. Del Monte Fruit & Oats is the first ready-to-eat wholesome oatmeal with a full serving of orchard-ripened fruit. These products address consumer trends of healthy living, nutritious snacking and convenience. Each Del Monte Fruit & Oats cup has 100% whole grain oats, 400mg of Omega-3 fatty acids and is a good source of fibre.

9. Del Monte’s goal is to transform the Refrigerated Produce and Deli sections with healthy snacks that consumers shopping the perimeter of the store are seeking. We developed Del Monte Fruit Crunch Parfait to meet this need with one full serving of fruit and non-dairy coconut crème and a crunchy granola topping. The parfaits are packed with two billion probiotics for digestive health and contain no artificial flavours or sweeteners.

10. A true testament to Del Monte's commitment to providing fresh, high quality fruits to families in inventive new ways, Del Monte Bubble Fruit is a first-of-its-kind snacking experience — combining the goodness of a classic fruit cup with bursting boba. Bubble Fruit does not contain any artificial colours or artificial sweeteners and contains a full serving of 100% real fruit, unlike the popping boba found in frozen yogurt or popular tea shops.

11. Innovation in the Philippine Market has largely focused on strengthening its core categories behind relevant functional benefits.

12. Health and wellness have been the anchor for new product introductions with consumer health needs in mind. Finding solutions to address emerging health issues has led to a host of innovative products that offer clinically-proven benefits, from promoting weight management and body fat reduction, to cholesterol lowering and bone health advantage.

13. Successful beverage innovations in the Philippines include:

a. Innovations on 100% Pineapple Juice aggressively expanded its relevance among a broader base of consumers, with ACE vitamins delivering improved immunity for the family; and 100% Pineapple Juice Fibre- Enriched delivering daily detoxification for young adults.

b. 100% Pineapple Juice Heart Smart with Reducol, a special blend of plant sterols and stanols that help lower bad cholesterol, and 100% Pineapple Juice Bone Smart, a calcium-fortified juice that has twice the level of calcium than a glass of milk, designed to provide the same benefit to lactose-intolerant consumers.

c. Del Monte Fit ‘n Right Juice Drinks with Green Coffee Extract and L- Carnitine clinically proven to help reduce fat when taken with diet and exercise.

14. Del Monte Quick ‘n Easy, a line of ready-to-use recipe sauces, dry mixes and marinades that make it easy for working moms to conveniently prepare a wide variety of meals for their families.

15. Contadina Olive Oil, Pasta Sauces, Pasta and Canned Tomatoes take to heart the Mediterranean philosophy of cooking to deliver authentic flavours with the finest ingredients grown and hand-picked from the most fertile regions of the world.

16. In Southeast Asia, S&W launched the organic version of the staple Prune Juice. This was followed by the launch of the organic version of Apple Cider Vinegar in Malaysia and Singapore.

17. As part of S&W’s plan to provide high-quality, healthy products globally, it launched Not From Concentrate (NFC) Pineapple Juice, made of 100% MD2 Pineapple Juice from the premium fresh pineapple variety. S&W offered NFC Pineapple Juice to customers as an ingredient for their pineapple smoothies, ice lollies or packaged NFC juice.

18. The Group entered the frozen fruit category using Nice Fruit’s revolutionary technology. Extra sweet and golden yellow pineapples from fully ripened fruits are cut into spears then frozen. Individually packaged frozen Pineapple Stick and frozen chunks called Golden Pineapple are sold in 7- Eleven Japan as an on-the-go healthy snack. The revolutionary technology allows the frozen or newly thawed pineapple to have the same physical properties as fresh cut pineapple. These are also sold in Hong Kong, China and South Korea.

.png?width=896&name=unnamed%20(1).png)

Del Monte is committed to health and nutrition. Consumers trust our brands and we ensure that our brands maintain this trust from one generation to the next.

We take a leadership role in meeting consumer preferences. We understand that consumers are becoming increasingly interested in learning about the ingredients in their food and are often looking for positive health properties such as low-fat or low-sugar. This emphasis on health benefits has ongoing implications for product design and sourcing.

1. In the US, Del Monte is the first major food producer to voluntarily adopt nutritional labeling on all food products.

2. Almost all of our products contain positive nutrients and majority are considered healthy.

3. We aim to have a good number of our products in the US provide at least half a cup of fruits or vegetables per serving and to meet healthy nutrient levels as recommended by the FDA. The majority of our produce are picked and packed on the same day – 97% without preservatives.

4. The majority of our products in the US are low in fat and we carry several specialised product lines: organic, no sugar added, low-salt, reduced-salt and low in calories for those seeking additional health benefits or following specific dietary regimes.

5. Within existing categories, DMFI has a significant competitive set of No Sugar added fruit products and No Salt Added and Reduced Sodium vegetable products relative to other branded players.

6. In the US, we began the process of verifying non-genetically modified organisms (GMO) ingredients from suppliers and sourcing replacement non- GMO ingredients where necessary.

7. DMFI has converted all Del Monte tomato products as well as nearly 100% of Del Monte fruit and vegetable products to non-Bisphenol A (BPA) linings.

8. All added ingredients in Del Monte vegetables, single-serve fruit snacks and most tomato products have been non-GMO, representing a majority of the Company’s product line.

9. In Asia, we anchor our nutrition platforms on weight management, heart health and bone health which give support to the immune system and aid in healthy digestion.

Consumer scanning the product details

Part of our commitment to ensure that our products are safe is having a robust traceability programme in place. With globalisation, our products reach more consumers. In order to protect consumers’ health, the traceability programme allows us to quickly identify the origin of the product, should an event arise, from its source and production to retailer. With this knowledge, we are equipped to handle consumer questions with confidence and in a timely manner. Having a reliable traceability programme enables the Group to have an effective process to identify a defective product or component and to execute the recall process if warranted.

1. The Group conducts periodic quality audits with our co-manufacturers to ensure compliance with our standards.

2. In the US, DMFI conducted 50 mock recalls covering Del Monte facilities, co- packers and distribution centres. We abide by the federal food safety requirements by maintaining a product traceability programme that allows us to track products shipped to our customers.

3. We have significantly enhanced this traceability programme to allow faster and more accurate traceability using electronic tracking of product movement.

4. Del Monte conducts extensive Risk Assessment/Hazard Analysis and incorporates actions to assure that the products and ingredients meet the highest Del Monte standards prior to introduction in the marketplace.

5. The system is tested frequently and test results are used to drive continuous process improvements.

6. Del Monte also maintains records that allow the Company to determine the source of the ingredients used in its products.

7. In the Philippines, our standards to trace products to their production date comply with the standards of the BRC. These standards apply to both our own facilities and our toll manufacturers.

8. A total of 43 Del Monte facilities and co-packers conducted mock-up traceability exercises in the Philippines, and within the standard traceability time of 4 hours.

9. Traceability assessment is conducted during certification and customer audits of our facility as well as our toll manufacturers.

Del Monte 100% Pineapple Juices with functional benefits

Our Group understands the need to have a packaging that attracts consumers and strives to make a positive influence on the environment.

We believe more efforts need to be exerted to maintain the quality and safety of our products as well as regulate our environmental impact. It gives us double incentive to rework our product packaging in a more environment-friendly manner.

1. The Company provides a hotline in the DMFI website to enable customers to ask detailed questions and provide feedback on the products.

2. DMFI began labeling most vegetables, fruit cup snacks and many more tomato products as non-GMO.

3. In the US, Del Monte was the first manufacturer to work with the USDA for non-GMO verification for corn products for consumer assurance on sweet corn products.

4. We have converted 100% of our branded tomato products and nearly 100% of our branded fruit and vegetable products to non-BPA lining in the US.

5. Polyester material is the alternative lining material for our vegetable and fruit products while vinyl is the alternative used for our tomato cans. The linings meet the requirements of California’s Prop. 65, ensuring that they do not contain phthalates or BPA and comply with all FDA and European Food Safety Authority standards. The coating components are also compliant with the United States Environmental Protection Agency and Regulation for Registration, Evaluation, Authorisation, and Restriction of Chemicals.

6. Del Monte in the Philippines has 100% BPA-Non Intent for all packaging materials in the cannery and its toll packers.

7. We also innovated our packaging to make it more convenient for consumers. Our juices come in resealable one litre cartons.

Contadina (only accessible in the Philippines)

Del Monte Careersc/o 17 Bukit Pasoh Road Singapore 089831 Tel: (65) 6324 6822 Fax: (65) 6221 9477